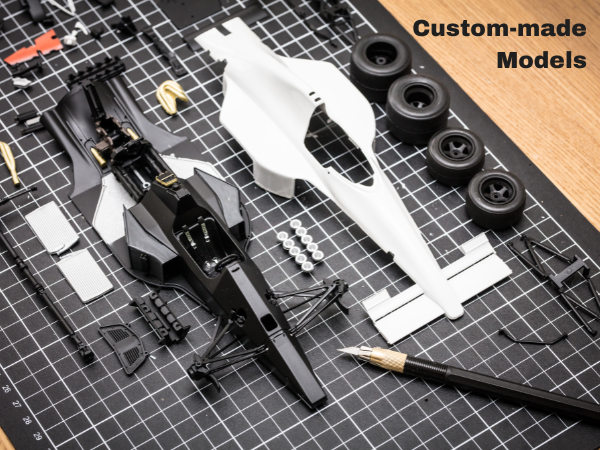

Custom-made models offer enthusiasts a unique opportunity to own a miniature version of their dream vehicle or a replica of a cherished classic. Whether you're an avid collector, a hobbyist, or looking for a special gift, having a custom model car made can be a rewarding experience. Here's a step-by-step guide to help you navigate the process.

1. Define Your Vision

Identify the Subject: Decide on the make, model, and year of the vehicle you want. Whether it's a classic muscle car, a modern supercar, or a beloved family vehicle, having a clear vision is crucial.

Detail Specifications: Consider the level of detail you want. This includes the colour, interior design, engine specifics, and any unique features or modifications.

Choose Your Production Method: Modern custom models can be created through traditional hand-crafting techniques or 3D printing technology. Each method has distinct advantages:

- Traditional Hand-Crafted: Offers artisanal quality, traditional finishing techniques, and a bespoke feel. Ideal for collectors seeking premium craftsmanship.

- 3D Printed Models: Provides faster production times, greater design flexibility, and often lower costs. Perfect for intricate details and modern designs.

2. Research Custom-made Modellers

Find Reputable Makers: Look for experienced and reputable custom-made model makers. You can find these through online searches, hobby forums, and recommendations from other collectors.

Review Portfolios: Examine the portfolios of potential makers to ensure their style and quality meet your expectations. Look for detailed photos of previous projects and read customer reviews.

3D Printing Specialists: If considering 3D printing, look for makers who specialise in resin printing (which offers superior detail compared to standard FDM printing) and have experience with model car finishing and painting.

3. Initial Consultation

Contact the Maker: Reach out to your chosen model maker to discuss your project. Be prepared to provide detailed information about your desired model and any specific requirements.

Discuss Feasibility: Some customisations may be challenging or costly. Discuss the feasibility of your project, including materials, scale, and special features.

Production Method Discussion: If you're considering 3D printing, discuss the level of detail achievable, post-processing requirements (sanding, priming, painting), and whether the maker can provide a fully finished model or just the printed parts.

4. Cost Estimation and Timeline

Get a Quote: Request a detailed cost estimate, which should include materials, labour, and any additional fees. Custom-made models can be a significant investment, so ensure you understand the pricing structure.

Typical Price Ranges: As a general guide, custom 1:43 scale models typically start from £200-£500, whilst 1:18 scale models generally range from £500-£1,500 or more, depending on complexity and detail level. 3D printed models may fall at the lower end of these ranges if supplied unpainted, or match traditional pricing for fully finished pieces. (Note: These are approximate industry ranges as of 2024 and can vary significantly based on the maker, materials used, level of detail, and specific customisation requirements.)

Timeline - Critical Information:

Traditional Hand-Crafted Models:

- Standard Projects: Most custom models take 3-6 months to complete from initial consultation to delivery

- Complex Projects: Highly detailed or intricate builds can take 6-12 months or longer

- Maker's Schedule: Popular model makers often have waiting lists of several months before they can even begin your project

3D Printed Models:

- Printing Time: The actual printing process typically takes 1-3 days depending on size and detail

- Post-Processing: Cleaning, sanding, priming, and painting add 2-6 weeks to the timeline

- Total Timeline: Expect 4-12 weeks from design approval to finished model

- Maker's Queue: Even with faster production, popular 3D printing services may have waiting lists

Planning for Christmas Delivery: If you're hoping to receive a custom model as a Christmas gift, timing is absolutely critical:

Traditional Methods:

- October Start: Too late for most makers - you're unlikely to receive the model before Christmas

- November/December Start: Far too late - custom models cannot be rushed to meet holiday deadlines

- Recommended Timeline: Begin your project no later than March-April to ensure Christmas delivery

- Ideal Planning: Start discussions in January-February to account for consultation, design approval, and production time

3D Printing:

- October Start: Potentially feasible if the maker has capacity and design is straightforward

- November Start: Risky - only consider if you're ordering an unpainted print or the maker guarantees the deadline

- December Start: Too late for finished models

- Recommended Timeline: Begin by July-August for comfortable Christmas delivery

- Ideal Planning: Start in May-June to allow time for design revisions and any reprints if needed

Remember: Custom model makers experience their busiest periods in spring and summer as collectors plan ahead for Christmas gifts. Starting early also gives you time to make design changes without jeopardising your deadline.

5. Design and Approval

Review Designs: The maker will provide design sketches or digital renderings of your custom model. Review these carefully to ensure all details match your vision.

3D Design Files: If using 3D printing, you may receive digital 3D models (CAD files) to review. Some makers offer the option to make minor adjustments at this stage.

Approval: Once you are satisfied with the design, give your formal approval to proceed. This step is crucial as changes later can be more difficult and costly.

6. Production Process

Regular Updates: Request regular updates on the progress of your model. This can include photos and descriptions of each stage of the build.

Quality Assurance: Ensure that the maker adheres to high-quality standards throughout the production process. Attention to detail is key in custom-made models.

3D Printing Stages: If your model is 3D printed, expect updates at key stages: printing completion, post-processing (cleaning and curing), priming, painting, and final assembly.

Be Patient: Remember that quality craftsmanship takes time. Rushing the process can compromise the final result.

7. Final Review and Delivery

Final Inspection: Once the model is complete, review it thoroughly. Check for accuracy in details, paint quality, and any agreed-upon custom features.

3D Print Considerations: For 3D printed models, check for layer lines (though high-quality resin prints should have minimal visible lines), paint finish quality, and structural integrity.

Delivery Arrangements: Discuss delivery/collection options with the maker. Ensure that the model is packaged securely to prevent damage during transit.

8. Display and Care

Display Options: Consider how you will display your custom-made model. Display cases can protect the model from dust and damage whilst showcasing its beauty.

Maintenance: Regularly dust and clean your model car to maintain its appearance. Avoid exposure to direct sunlight and extreme temperatures to prevent fading or warping.

3D Printed Model Care: Resin 3D printed models should be kept away from prolonged UV exposure, which can cause brittleness over time. Handle with care as some resin materials can be more fragile than traditional diecast.

Conclusion

Getting a custom model made is a meticulous but rewarding process that requires careful planning and patience. Whether you choose traditional hand-crafting or modern 3D printing technology, both methods can deliver stunning results when executed by skilled makers.

The key to success is starting early - particularly if you have a specific deadline in mind. Allow plenty of time for consultation, design, production, and any unforeseen delays. 3D printing offers a faster alternative to traditional methods, but still requires adequate time for finishing work to achieve collector-quality results.

Enjoy the pride of owning a unique piece that reflects your passion and attention to detail.

PLEASE NOTE: Diecast Model Centre are not model makers, nor can we offer any recommendation or assistance in finding a suitable model maker for your custom-made model.

This guide has been written in response to the many enquiries we receive for custom-made models. By following it, enthusiasts and collectors alike can navigate the process of creating a custom-made model car, ensuring a satisfying and high-quality result.

Share:

The Rise of 1:64 Scale Model Cars: A Shift from 1:43 Scale

Exciting New Model Announcements from Norev